Photo Engineer

Subscriber

Well, before I start I should refer you to USP-5,248,418. This patent by Bill Munch sets the stage for all that follows here.

Due to solubility of starting materials, an emulsion is usually restricted to about 1/2 mole (about 50 grams) of silver per liter of emulsion and between 2% and 10% gelatin. This is further diluted when the emulsion is washed free of salts. An early solution was to use Phthalated Gelatin, now sold by the Photographers Formulary and fully described in my DVD. (Yes, it is done and I've posted a picture here from the footage that shows one scene of this method.) I have also described this method here in this forum.

The preferred method at Kodak which is now in use and described by Bill in his patent involves Reverse Osmosis (RO) and/or Ultrafiltration (UF).

In these methods, salts and water may be removed by passing the emulsion over a semi-permeable membrane just like a kidney dialysis machine. So, you see that the emulsion can be washed and concentrated both.

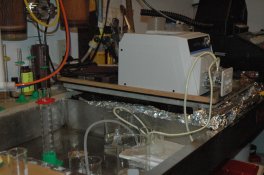

I now have access to the equipment needed for both methods and will begin adapting my emulsions to use any of the 3 methods in the future (PA, RO or UF). As I go along, I hope to document the work with suitable commentary and pictures. I'm putting this up just to let you know what I've been up to lately.

I am also about to embark on making a new camera speed emulsion after a long series of experiments based on advice from friends. I'll keep you posted on this as well as it is integral to the new wash methods.

PE

Due to solubility of starting materials, an emulsion is usually restricted to about 1/2 mole (about 50 grams) of silver per liter of emulsion and between 2% and 10% gelatin. This is further diluted when the emulsion is washed free of salts. An early solution was to use Phthalated Gelatin, now sold by the Photographers Formulary and fully described in my DVD. (Yes, it is done and I've posted a picture here from the footage that shows one scene of this method.) I have also described this method here in this forum.

The preferred method at Kodak which is now in use and described by Bill in his patent involves Reverse Osmosis (RO) and/or Ultrafiltration (UF).

In these methods, salts and water may be removed by passing the emulsion over a semi-permeable membrane just like a kidney dialysis machine. So, you see that the emulsion can be washed and concentrated both.

I now have access to the equipment needed for both methods and will begin adapting my emulsions to use any of the 3 methods in the future (PA, RO or UF). As I go along, I hope to document the work with suitable commentary and pictures. I'm putting this up just to let you know what I've been up to lately.

I am also about to embark on making a new camera speed emulsion after a long series of experiments based on advice from friends. I'll keep you posted on this as well as it is integral to the new wash methods.

PE