Basically as Frank summarized in item #3 above, how much visible spectrum is let thru the ink does not correlate well with how much UV is. That is the reason why your measurements on 361T would diverge from an experimental outcome. If you had a densitometer with UV capability, the results would have been closer. Even then I suspect there would be some discrepancy since different chemistries might have peak sensitivity at different UV bands. So the exact position of Dmax maximum might also be process-dependent. I think that's the reason, there is no substitute to empirical testing to arrive at the best blocking color for a given digineg/process combination.

Hope this helps...

:Niranjan.

Any comment of yours helps a lot. Thanks! I made the measurements with UV (the X-Rite 361T has both UV and Ortho mode). To the best I can determine, the UV spectrum is 340-406 nm. Even though emulsions are sensitive to particular UV wavelengths, I wonder if the difference would be significant. A half stop? Hard to imagine. They're certainly good enough for my application (running computer simulations).

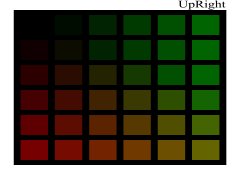

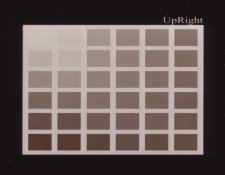

I think we should be looking at the printer, and not the process. Here is what I suspect is going on. On your printer, green 51/128/0 prints with higher density than black 0/0/0. If I printed your grid on my P400, it will be just the opposite.

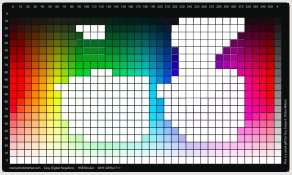

If you would be willing to upload the source file for your color grid, I'll make a transparency on my P400 and measure the UV densities of all 121 cells. If I had your physical transparency, I'd measure that too!

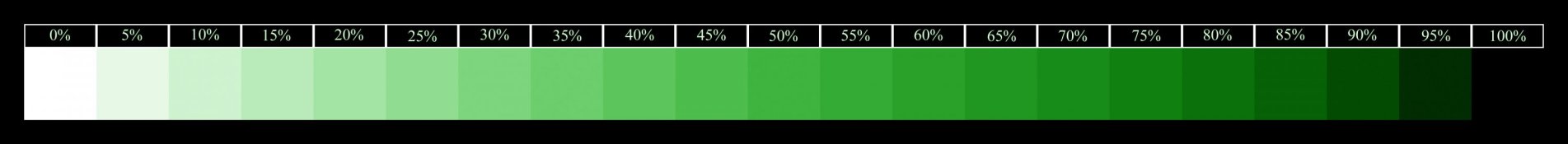

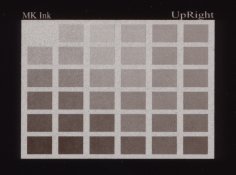

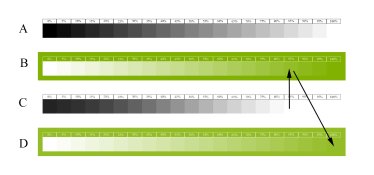

Earlier in this discussion, I posted a graph with four density curves. These were for four columns of the Mrhar HSB color grid: Red, Green, Blue, and Gray. I'm posting it again below. I printed a target using classic cyanotype, which has an exposure scale of 1.17 (determined by me). If I draw a horizontal line through the graph at 1.17, and then drop verticals down to the HSB axis from where the line intersects each curve, it should tell me which HSB value to use for that Hue to get the correct negative density range. The agreement is perfect! In fact, I suspect the transmission densities give a more accurate color than the 5% steps of the target!

and may be look for an alternative. Or change the chemistry/process to accommodate the lower UV density if there is a leeway there.

and may be look for an alternative. Or change the chemistry/process to accommodate the lower UV density if there is a leeway there.