RDWestPR

Member

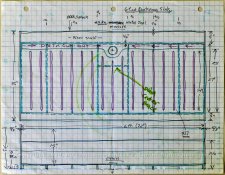

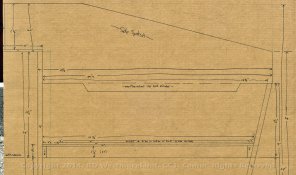

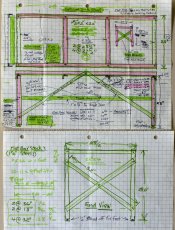

I'm nearly finished building my new plywood sink for Carbon Transfer Print making, but I have a question about finish. I plan to waterproof the thing with epoxy resin. My question is- Do I need to use a filler/sealer coat on the wood first or can I go straight to using the epoxy? I plan to put one coat on the bottom and 2 on top, but I'm open to ideas. I tried to score a used darkroom sink, but no luck finding one in Puerto Rico. Here are a couple of shots of it, as of yesterday. it's 27" x 6 feet on the inside.